Learn more about our αSTEP family of products.

Closed Loop Stepper Motors

AZ Series Stepper Motors with Mechanical Absolute Encoder - αSTEP

The αSTEP AZ Series stepper motors offer high efficiency, low vibration and incorporates our newly developed Mechanical Absolute Encoder for absolute-type positioning without battery back-up or external sensors to buy. Closed loop performance without hunting or gain tuning. Available with a built-in controller or pulse input driver which substantially reduces heat generation from the motor through the use of high-efficiency technology. Requires αSTEP AZ Series Driver.

- Battery-Free, Mechanical Absolute Encoder Stepper Motors

- Closed Loop Performance, No Hunting or Gain Tuning

- AC or DC Input Types

- Parallel Shaft and Right Angle Geared Types for Higher Torque, Space Savings

- Electromagnetic Brake Type Available

- αSTEP AZ Series Stepper Motor Driver Required*

AR Series Closed Loop Stepper Motors - αSTEP

The αSTEP AR Series stepper motors offer high efficiency, low vibration, continuous operation with the security of closed loop performance without hunting or gain tuning. Available with a built-in controller or pulse input driver, the system substantially reduces heat generation from the stepper motor through the use of high-efficiency technology. The αSTEP AR Series also achieves up to 40% less power consumption, improved angle accuracy and is capable of driving large inertia loads. For use with αSTEP AR Series Drivers.

- High-Efficiency, Continuous Operation Stepper Motors

- Closed Loop Performance, No Hunting or Gain Tuning

- AC or DC Input Types

- Parallel Shaft and Right Angle Geared Types for Higher Torque, Space Savings

- Electromagnetic Brake Types

- αSTEP AR Series Stepper Motor Driver Required*

Closed Loop Stepper Motor Performance - αSTEP

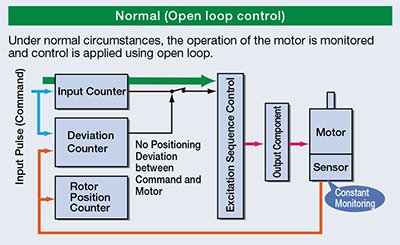

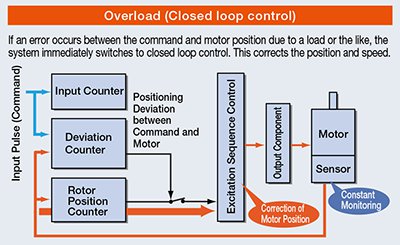

These stepper motors use our αSTEP closed loop technology to maintain positioning operation even during abrupt load fluctuations and accelerations without hunting or gain tuning. The rotor position detection sensor monitors the rotation speed and amount. When an overload condition is detected, it will instantaneously regain control using the closed loop mode. When an overload condition continues it will output an alarm signal, thereby providing reliability.

Normally Operates in Open Loop Control for the Same Ease of Use as a Stepper Motor

High Response

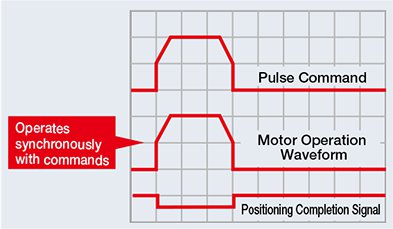

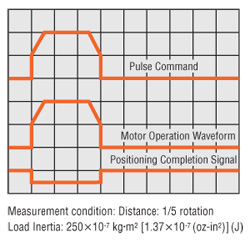

By utilizing the high responsiveness of the stepper motor, moving a short distance for a short time is possible. The motors can execute commands without lag.

Holding the Stop Position without Hunting

During positioning, the motor stops with its own holding force without hunting. Because of this, it is ideal for applications where the low rigidity of the mechanism requires absence of vibration upon stopping.

Tuning-Free

Because it is normally operated with open loop control, positioning is still possible without gain adjustment even when the load fluctuates due to the use of a belt mechanism, cam or chain drive, etc.

Switches to Closed Loop Control during Overload for More Reliable Operation like a Servo Motor

Continues Operation Even with Sudden Load Fluctuation and Sudden Acceleration

It operates synchronously with commands using open loop control during normal conditions. In an overload condition, it switches immediately to closed loop control to correct the position.

Alarm Signal Output in Case of Abnormality

If an overload is applied continuously, an alarm signal is output. When the positioning is complete, and END signal is output. This ensures the same level of reliability as a servo motor.

No Hunting

Since these are stepper motors, there is no hunting problem. Therefore, when the motor stops, its position is completely stable and does not fluctuate. Closed Loop stepper motors are ideal for applications in which vibration would be a problem.

High Response

Like conventional stepper motors, closed loop stepper motors operate in synchronism with command pulses. This makes short stroke positioning possible in a short amount of time.

No Gain Tuning

Gain tuning for servo motors is critical, troublesome and time-consuming. Since these are stepper motors, there are no gain tuning requirements. Low rigidity applications, such as a belt and pulley system, are ideal for closed loop stepper motors.

Stepper Motor Comparison

Product Series |

||

Features |

Closed Loop, |

Closed Loop, |

Feedback Type |

Mechanical Absolute |

Resolver |

Basic Step Angle |

0.36° |

0.36° |

Driver Required |

AZ Series |

AR Series |

Driver Power Input |

AC or DC |

AC or DC |

Frame Sizes |

0.79 in. (20 mm) NEMA 8 |

1.10 in. (28 mm) NEMA 11 |

Available Options |

Geared Type |

Geared Type |

Max. Holding Torque |

2.8 oz-in up to 752 lb-in |

42 oz-in up to 442 lb-in |

0.02 N·m up to 85 N·m |

0.3 N·m up to 50 N·m |

|

Learn More |

- Hybrid Stepper Motors and αSTEP Hybrid Control Systems

- Eliminating External Sensors with the αSTEP AZ Series Absolute Encoder Stepper Motors

- αSTEP Battery-Free, Absolute Encoder Stepper Motors

- Low Heat, Continuous Duty Stepper Motors

- Stepper Motor Gearheads

- IP Ratings - Degree of Protection

- Motor Sizing Calculations