Product Information

Solutions

Technical Information

Motor Sizing

Downloads

Virtual Showroom

Contact Us

Linear Actuators > Lead Screw Actuator Attachments > Stepper Motor Linear Actuator Attachment

Stepper Motor Linear Actuator Attachment

Stepper Motor Linear Actuator Attachment

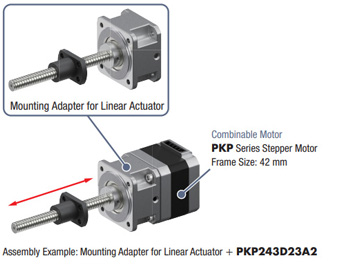

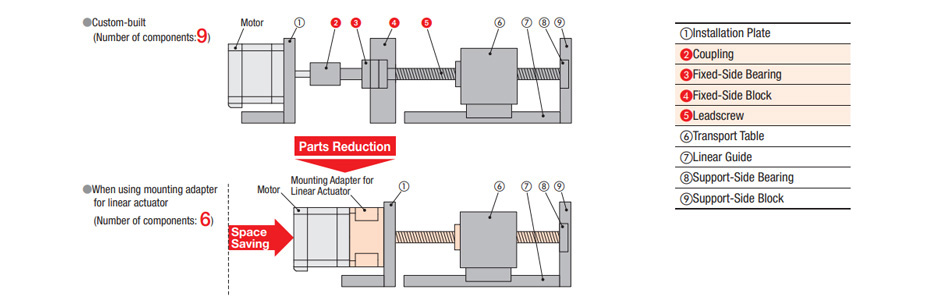

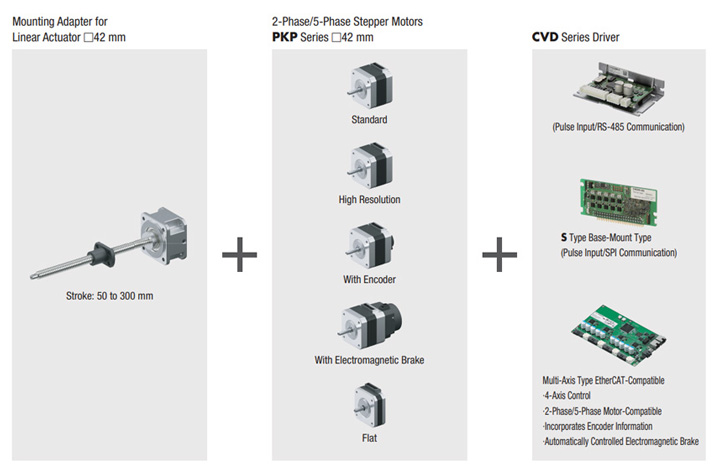

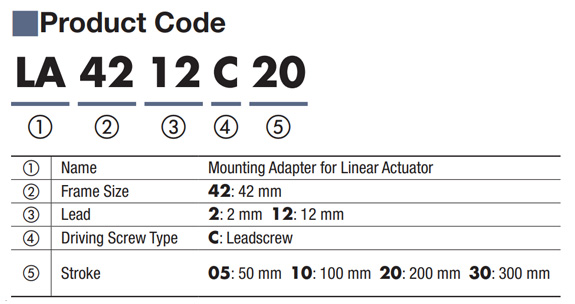

The Mounting Adapter for Linear Actuators is a linear motion mechanism with a lead screw and resin nut. It saves space and reduces design time compared to a custom-built mechanism. To use with 2-Phase and 5-Phase stepper motors PKP Series frame size 42mm.

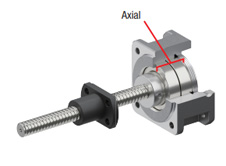

- Linear motion mechanism with a leadscrew and a resin nut

- Easy installation without the need of coupling to an Oriental Motor stepper motor

- For the 42 mm frame size, thrust and self locking force are both a max. 100 N