Product Information

Solutions

Technical Information

Motor Sizing

Downloads

Virtual Showroom

Contact Us

Network Products > Multi-Axis Controllers > MRC Robot Controller EtherNet/IP (DC Input)

AZ Series EtherNet/IP™ Compatible Drivers (AC Input)

αSTEP Hybrid Step-Servo

Robot Controller EtherNet/IP™ (DC Input)

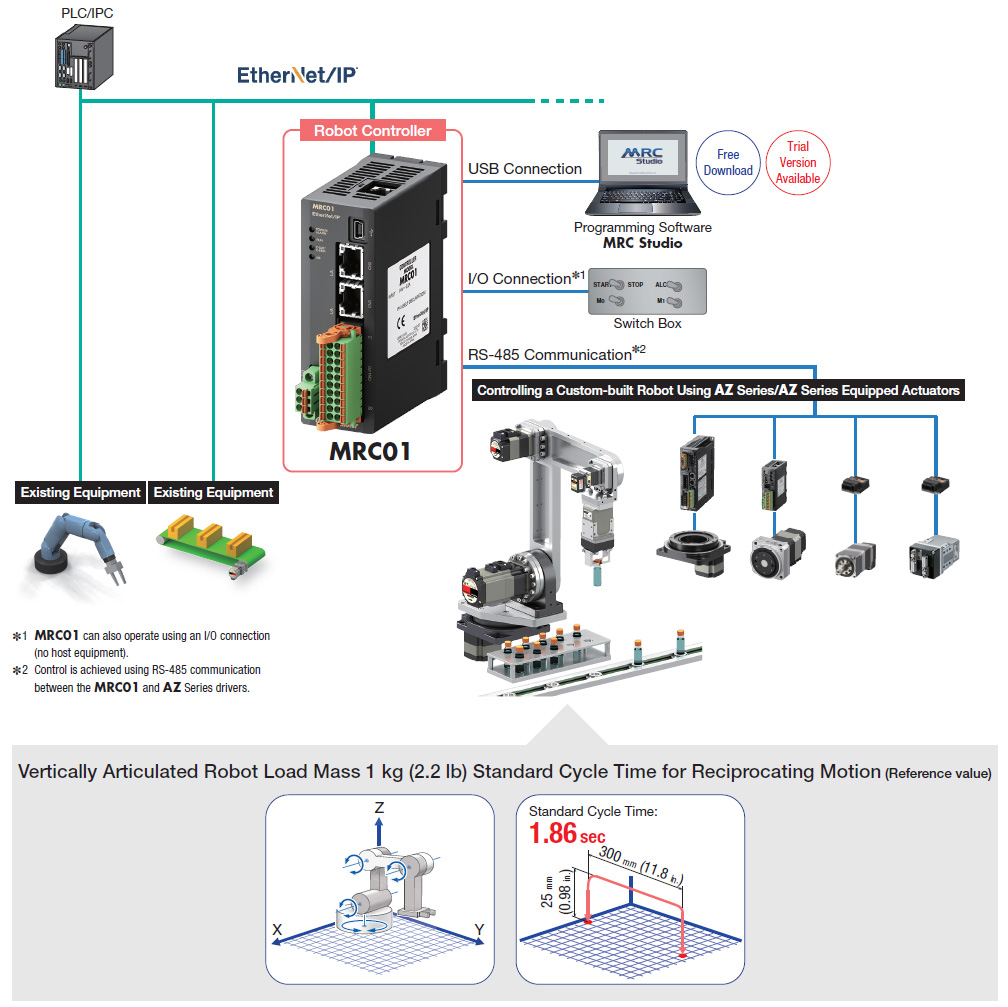

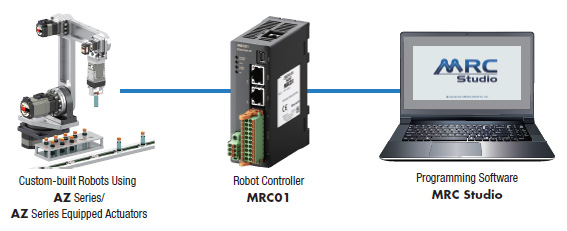

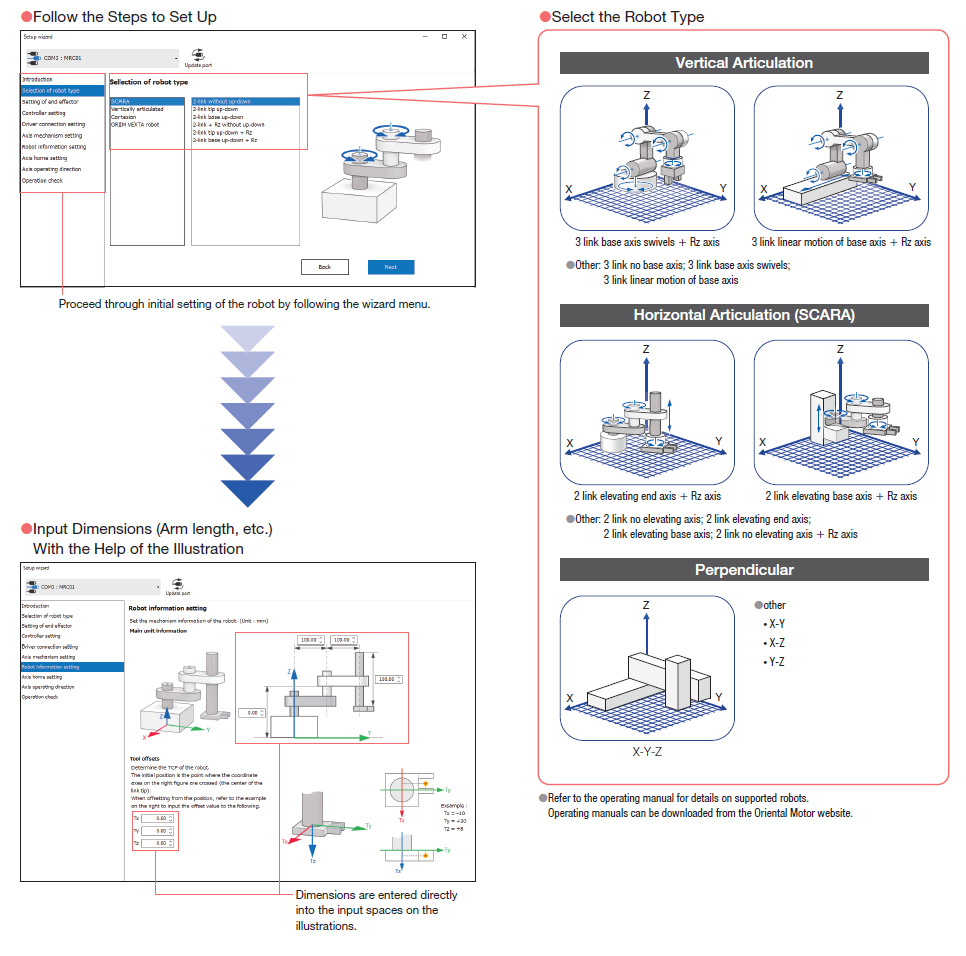

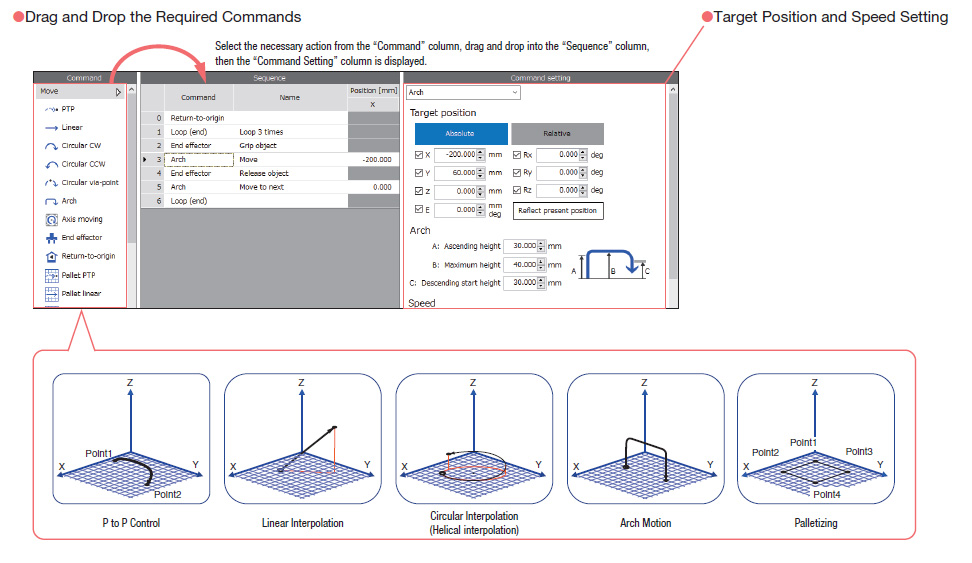

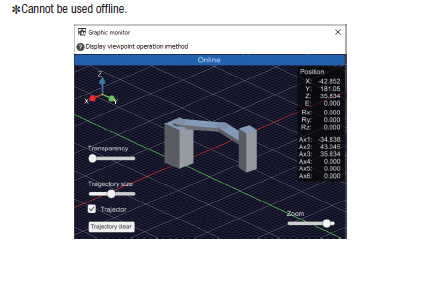

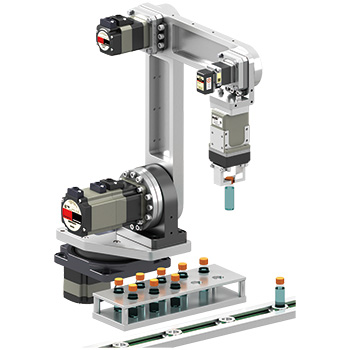

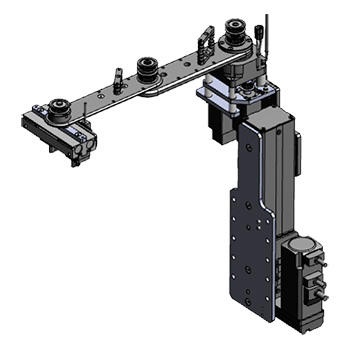

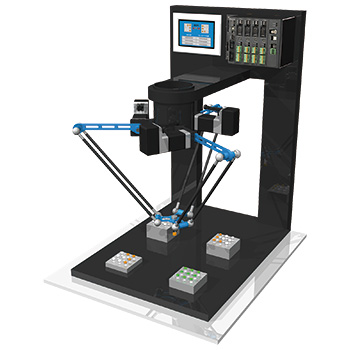

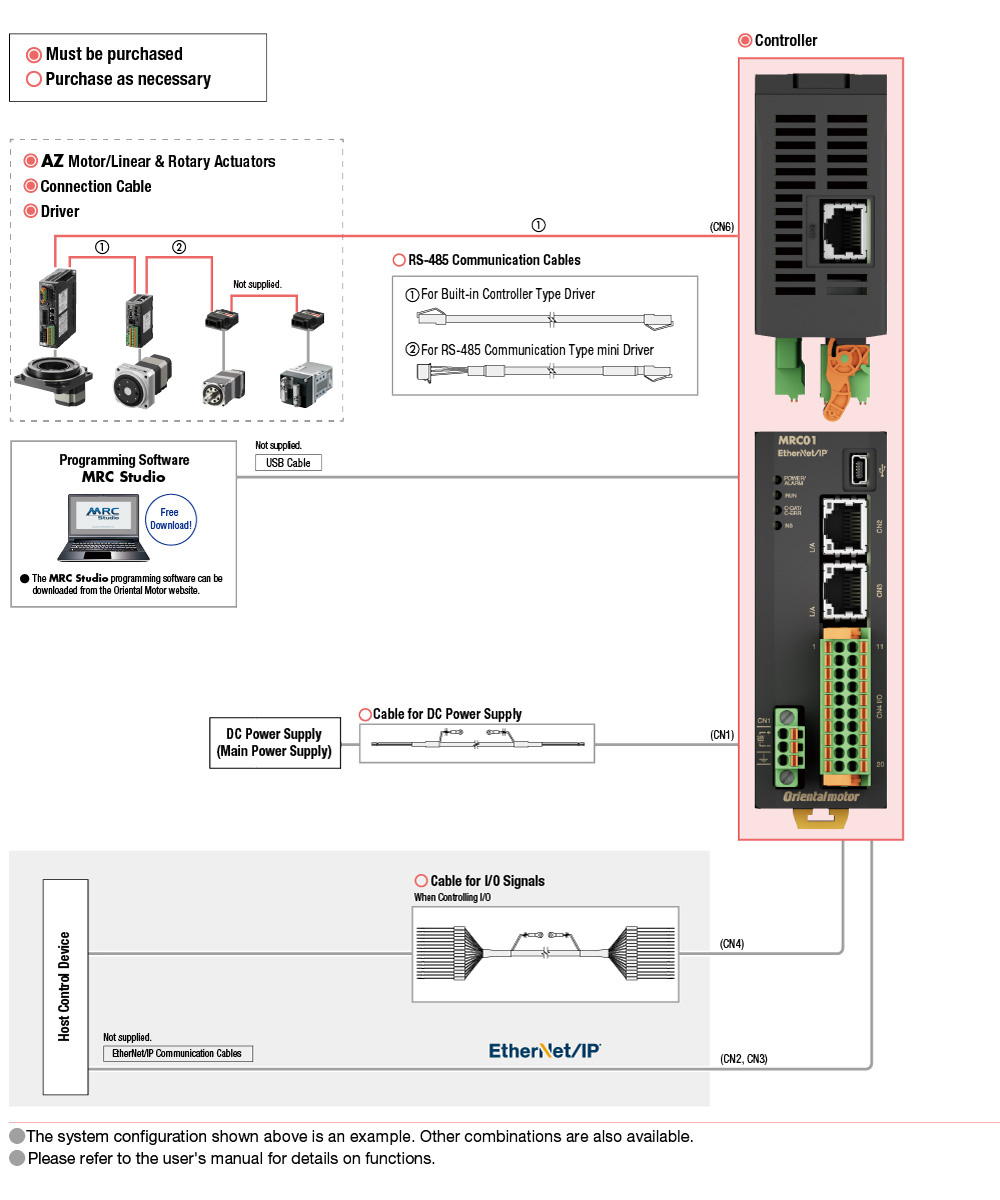

The MRC01 robot controller supports easy programming and control of in-house designed custom built robots with 3 simple steps: "Initial Setup", "Operating Programming" and "Operational Checking".

Use the AZ Series family of products to support your in-house design for improved performance and ease of use.

- Easily introduce custom-built robots to existing systems

- Direct control via EtherNet/IP™

- Easy setup even for beginners (no ladder logic)

- Experience the "MRC Studio" programming software (trial version) before purchase

- Use with AZ Series drivers: built-in controller type (AC/DC) or mini driver RS-485 communication type (24/48 VDC)

![]()

EtherNet/IP™ is a trademark of ODVA.

Need Help Sizing?

Please fill out and submit the appropriate product recommendation request form, and our technical support team will follow up with details on motor selection and software feasibility. We can also use your design drawing or CAD file if it works better for you.

Videos

Stepper Motors

Electric Linear Actuators / Linear Slides

Electric Linear Actuators / Cylinders

Rack and Pinion Systems

Rotary Actuators