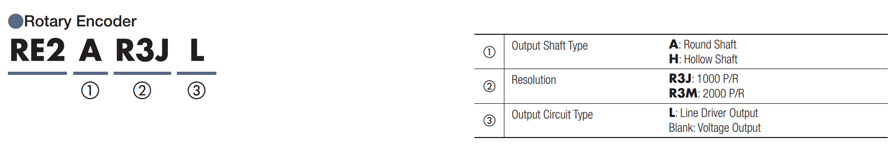

Small, Thin, and Lightweight High-Resolution Incremental Encoder

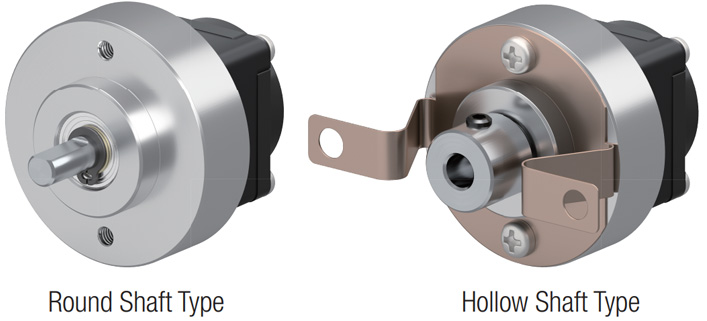

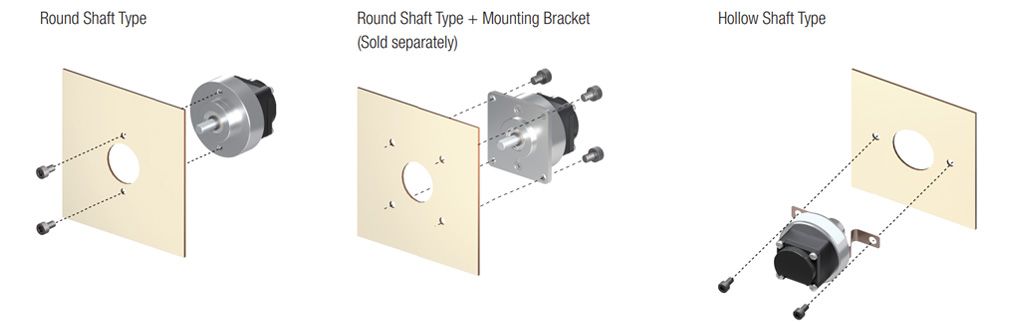

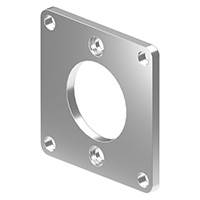

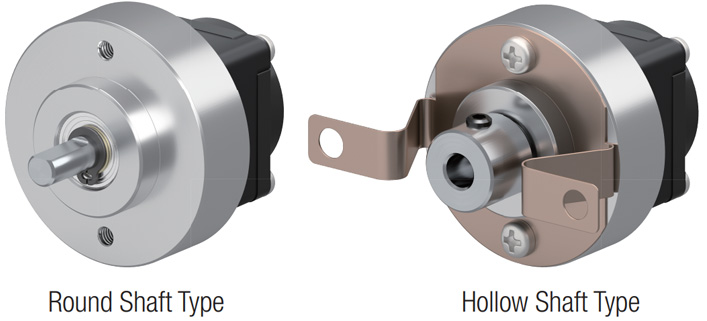

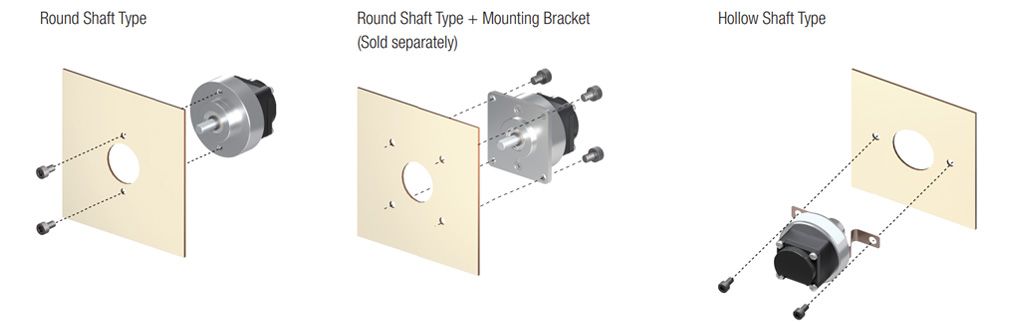

Because these are small, thin and lightweight, with an outer diameter of ϕ30 mm, depth of 22 mm, and mass of 33 g (round shaft type) / 38 g (hollow shaft type), they can be installed in tight spaces. It is also a high resolution (1000 P/R or 2000 P/R) incremental type.The Rotary Encoder is available in Round Shaft Type and Hollow Shaft Type.

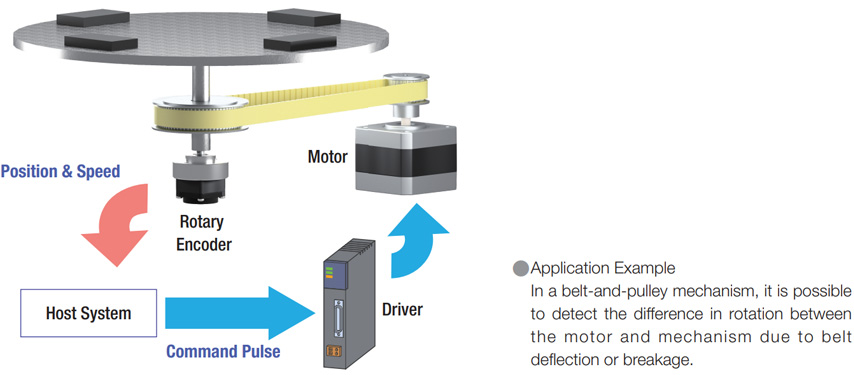

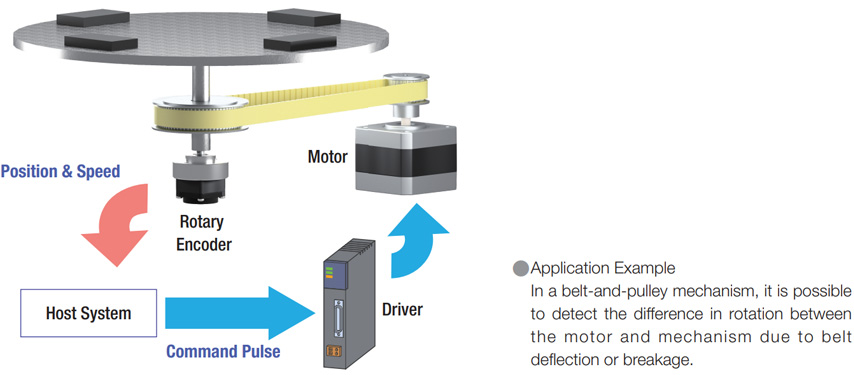

Actual Position, Speed and Rotation Direction of the Mechanism can be Detected

By installing a rotary encoder on a mechanism, a preventative maintenance system for that mechanism can be created.

Can Be Installed to Suit the Mechanism

By installing a rotary encoder on a mechanism, a preventative maintenance system for that mechanism can be created.

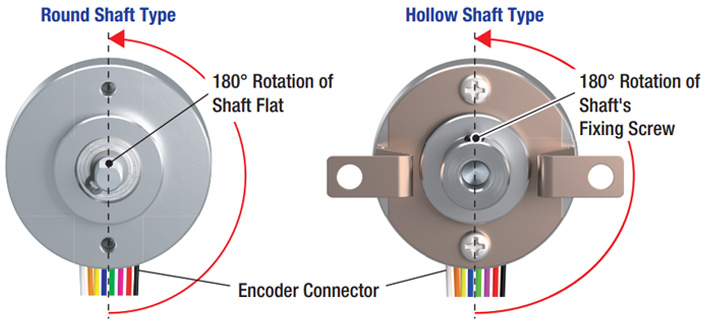

Aligning Mechanical Home and Z-Phase Signal Position is Easy

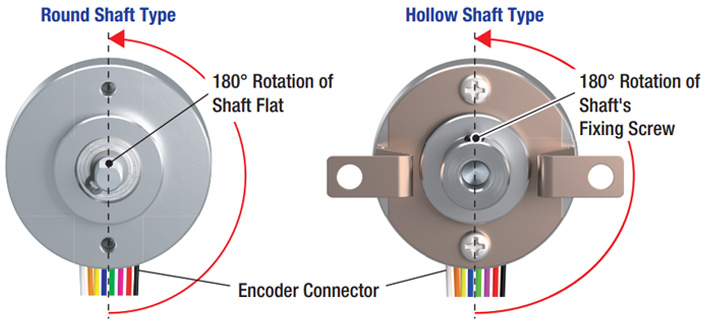

The Z-phase signal is output at the position where the shaft flat (round shaft type) or the fixing screw (hollow shaft type) has rotated 180˚ from the encoder connector. Use this as a guide when aligning the mechanical home and the Z-phase signal position.