NX Series Tuning Free Servo Motors

NX Series Tuning Free Servo Motors

The NX Series servo motors are capable of highly accurate control with easy operation, similar to stepper motors. These servo motors are specialized for high-response, high-precision positioning. As a motor capable of accurate rotation angle and speed control it can be used for a variety of equipment.

- Tuning Free

- Compact and High Power

- Wide Variable Speed Range

- Standard or Planetary Geared Type

- Electromagnetic Brake Types

- NX Series Driver Required*

Servo Motor Lineup

Output Power |

Motor Types |

Available Options |

Rated Torque |

Max. Instantaneous Torque |

||

Round Shaft (No Gear) |

Electromagnetic Brake |

22 oz-in |

0.159 N·m |

67 oz-in |

0.478 N·m |

|

| Planetary Geared | 6.3 ~ 28 lb-in |

0.716 ~ 3.22 N·m |

19 ~ 85 lb-in |

2.15 ~ 9.66 N·m |

||

Round Shaft (No Gear) |

Electromagnetic Brake |

45 oz-in |

0.318 N·m |

135 oz-in |

0.955 N·m |

|

| Planetary Geared | 12.6 ~ 56 lb-in |

1.43 ~ 6.44 N·m |

37 ~ 170 lb-in |

4.29 ~ 19.3 N·m |

||

Round Shaft (No Gear) |

Electromagnetic Brake |

90 oz-in |

0.637 N·m |

270 oz-in |

1.91 N·m |

|

| Planetary Geared | 25 ~ 144 lb-in |

2.87 ~ 12.9 N·m |

76 ~ 340 lb-in |

8.6 ~ 38.7 N·m |

||

Round Shaft (No Gear) |

Electromagnetic Brake |

180 oz-in |

1.27 N·m |

540 oz-in |

3.82 N·m |

|

| Planetary Geared | 50 ~ 220 lb-in |

5.72 ~ 25.7 N·m |

151 ~ 680 lb-in |

17.1 ~ 77.2 N·m |

||

Round Shaft (No Gear) |

Electromagnetic Brake |

330 oz-in |

2.39 N·m |

1010 oz-in |

7.16 N·m |

|

Standard Type Servo Motors

- 50 W (1/15 HP)

- 100 W (1/8 HP)

- 200 W (1/4 HP)

- 400 W (1/2 HP)

- 750 W (1 HP)

Easy Operation

As with a stepping motor, stable operation can be achieved in high inertia drive and belt mechanism drive applications without gain adjustment using the servo motors. Also, adjusting the gain manually enables operation under even more stringent load conditions.

Achieves High Inertia Drive

With automatic tuning, operation up to 50 times the rotor inertia is possible. With manual tuning, operation up to 100 times the rotor inertia is possible.

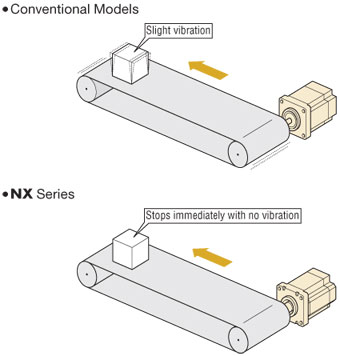

Achieves Smooth Operation with Belt Mechanisms

Belt mechanisms can be operated with the same performance as a stepping motor without the occurrence of vibration before stopping.

Driver Operation

Easy Handling

Basic settings and adjustments are made with switches and potentiometers on the front panel. This design allows for easy control without a computer and even saves the hassle of complicated UP and DOWN key operations.

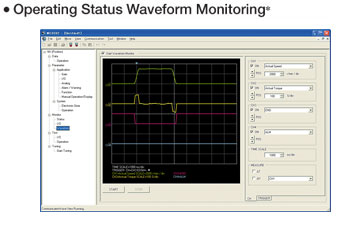

Easy Setting and Easy Monitoring

By using the control module (OPX-2A) [sold separately] or data setting software (MEXE02) [sold separately], it is possible to perform changing of parameters, function setting and monitoring that is better suited to your system.

4 Control Modes

Position Control

The built-in, high-resolution 20-bit absolute encoder enables highly accurate positioning of the servo motor.

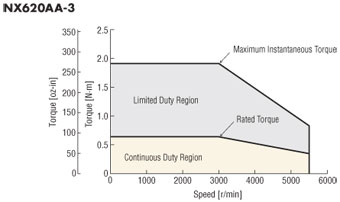

High Speed and High Response

High-speed positioning can be performed utilizing the high-speed and high response characteristics.

Maximum Speed 5500 r/min

Factory Setting Time 60 to 70 ms

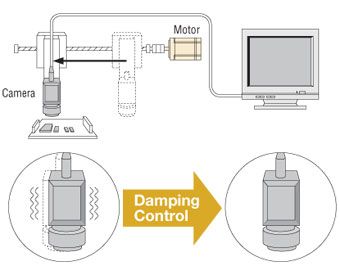

Damping Control

Eliminates load resonance by adjusting the potentiometer. This adjustment can be made easily and without searching for the resonance frequency.

<Application Example: Image inspection equipment>

Camera vibration during stopping can be suppressed by using the damping control.

Absolute System

Use as an absolute system by attaching an optional battery (sold separately) is possible. The current position of the encoder can be stored, so resetting after a blackout or similar occurrence is easy.

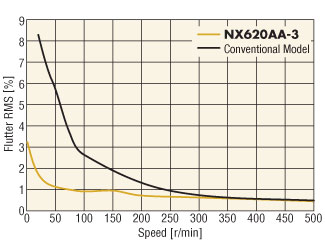

Speed Control

The reduction of servo motor cogging torque and the use of a high-resolution encoder have substantially reduced variation in rotation in the low-speed range (the flutter characteristic), resulting in smooth operation even at low speeds.

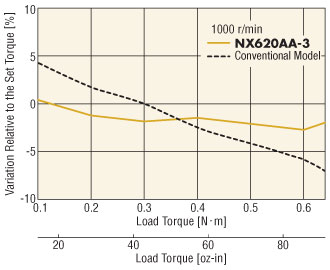

Torque Control

Variation of the generated torque relative to the set torque (torque accuracy) has been improved, resulting in highly accurate torque control.

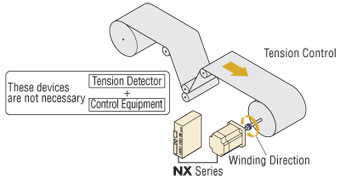

Tension Control

Tension control such as winding film can be easily performed without using a tension detector or control equipment using the servo motor.

Degree of Protection IP65

These motors conform to IP65 and are ideal for use in environments requiring dust resistance and water resistance. (Excluding installation surface and connector locations).

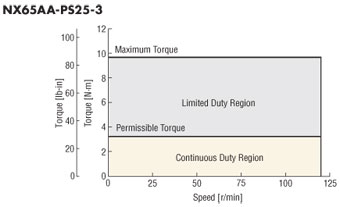

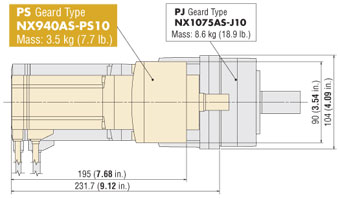

Planetary Gear Servo Motors (PS)

- 50 W (1/15 HP)

- 100 W (1/8 HP)

- 200 W (1/4 HP)

- 400 W (1/2 HP)

High Performance Geared Servo Motors

These geared motors with high permissible torque fully utilize the motor output torque.

Low Backlash

The backlash is 15 arc minutes (0.25°) max. These motors can be used in a wide range of applications.

Compact and Lightweight Design

Compared to the PJ geared types, these are compact, lightweight geared motors.

Electromagnetic Brake Option

- 50 W (1/15 HP)

- 100 W (1/8 HP)

- 200 W (1/4 HP)

- 400 W (1/2 HP)

- 750 W (1 HP)

These motors incorporate a non-excitation type electromagnetic brake. When power is accidentally cut off due to a blackout or other unexpected events, the electromagnetic brake holds the load in position to prevent it from dropping or moving.

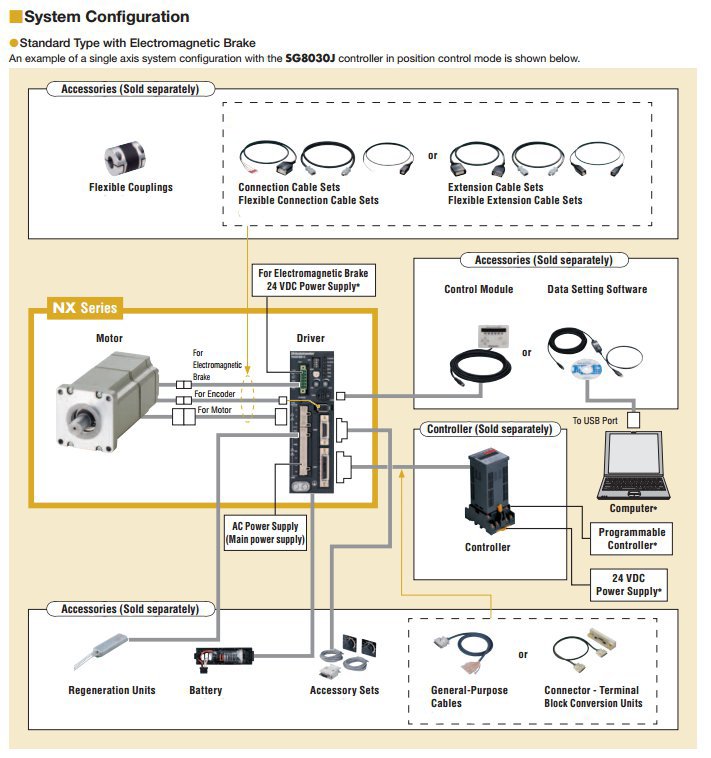

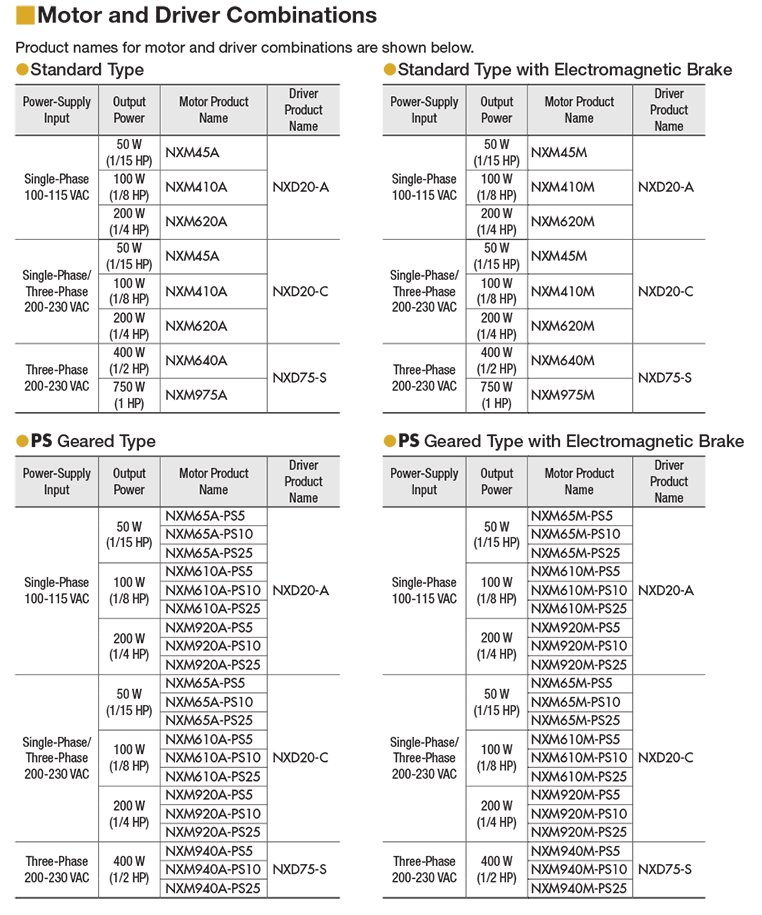

NX Series Drivers

The NX Series servo motor drivers allow for easy operation and control of the servo motors. 4 Control Modes are available: Position, Speed, Torque and Tension Control. The driver provides automatic tuning allowing for optimal performance without manual adjustments.

- Built-in Protective Functions

- Pulse Input Type

- Single-Phase 100-115 or Single-Phase, Three-Phase 200-230 VAC

SCX11 Universal Controller

The SCX11 is a highly-functional and sophisticated controller equipped with program editing and execution functions. Use the SCX11 as a stored program controller to connect to any of Oriental Motor's standard pulse input drivers. The SCX11 is also able to control the motor via serial communications such as USB, RS-232C and CANopen.

Cable Sets

These cables are used to connect or extend the distance between the motor and driver.

Required (sold separately).

Use a flexible motor cable if the motor is installed on a moving part or its cable will be flexed.

System Configuration

Motor and Driver Combinations

CAD / Manual Search

To locate product CAD and Operator Manuals please search using the product Item Number.